Graphic design is an integral part of modern packaging production. Packaging designs are created taking into account factors such as product branding, shelf appeal, functionality and product protection. They are visually striking and functional packaging solutions combining aesthetics, typography and structural design. The design team of Fin-Plast International first prepares the order according to the customer's request. The first sketch of the customer's dream design is drawn, on the other hand, if there are any changes or additions, the final adjustments are made according to this requirement. Product information is added to the approved design. Then it is prepared for printing. This is the stage of work that requires extreme attention and responsibility. After all these processes are finished, the mold of the finished design is prepared and finally the finished mold is sent to print.

Fin-Plast International's graphic design team with years of experience is a real source of creative power when it comes to seeing the customer's dream print on the product. We know that a flawless product depends on quality mold and tasteful design.

We are with you with our deep experience in this field, individual adaptation to the requirements of each client, financial advantages and most importantly, environmentally friendly ideas.

We offer printing services with the most vivid colors for the most famous and famous brands of the market. Thus, we produce matte, glossy, matte-glossy, paper-effect packaging with 8-color printing machines produced by the most famous producers in Europe.

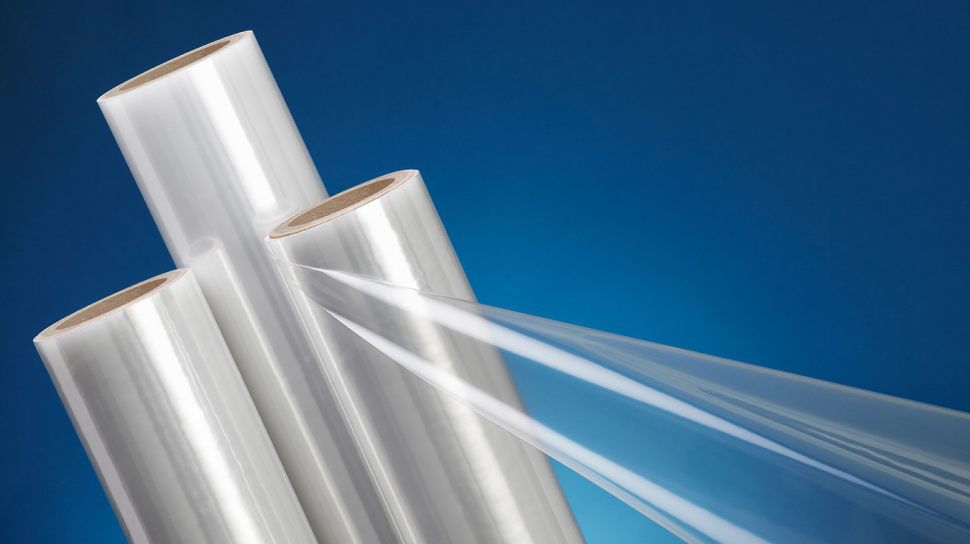

In addition to simple solvent-free or solvent-based operations, we are engaged in the production of 3-layer laminated products resistant to external influences. Different types of lamination films - PET, OPP, CPP, foil aluminum, PE, are available at our paper production facility.

All our products go through frequent and precise quality control checks at every stage of production to guarantee the full realization of customer-requested features.

The final step before delivering the ordered products to the customer is slicing. Thus, the finished product is sliced according to the required dimensions, packed and sent for delivery.

Various types of high-quality packages are produced in our enterprise. With handles, without handles, taqvi (with hot glue handles, cold glue) packages, with bellows, without bellows, with matte and glossy printing, with adhesive, etc. we produce packages.

At the request of our customers, delivery is carried out in accordance with Incoterms 2020.